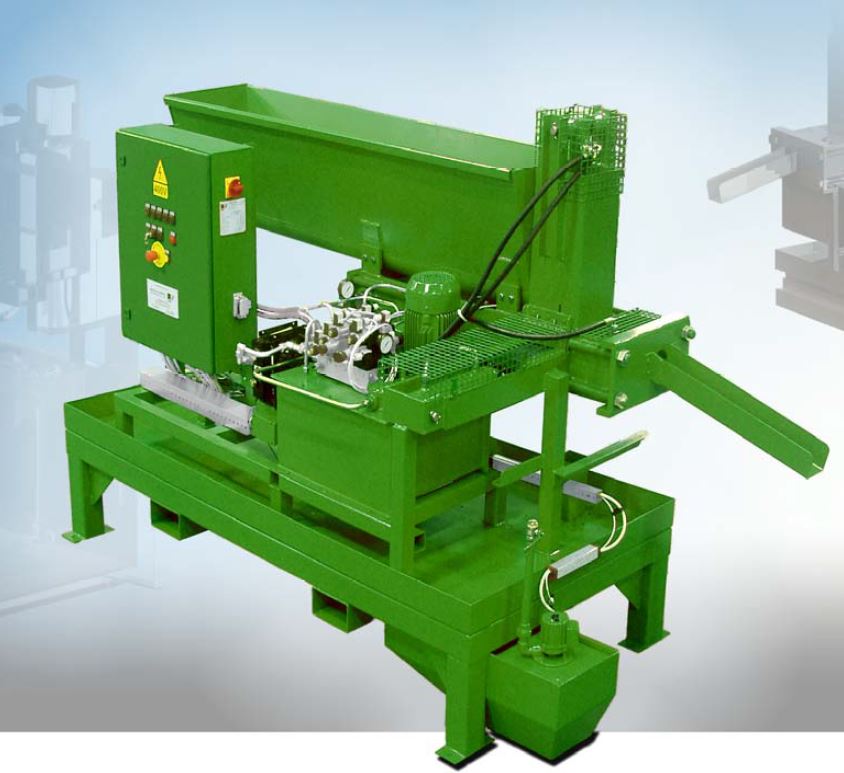

Sludge compactor: Reduce Waste and save coolant

Sludge, coming from a coolant filtration system, still contains oil and is an amor-phous mass. The compactor makes sure that a maximum amount of remaining oil is pressed out of the sludge, while the sludge itself is turned into easily-manageable and compact, dry packets. The sludge compactor is designed to fit perfectly under our filtration systems.

Benefits

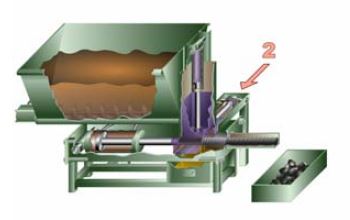

In 3 consecutive steps, presses reduce an amount of 100 kg humid substance into 16 kg of dry sub-stance. Transportation costs, to clear away the waste, and disposal costs are significantly reduced. The oil bill is reduced as well, since the recycled oil is led into the filtration process again.

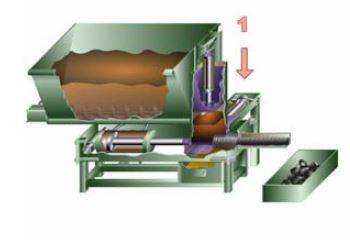

Mode of operation

The sludge from the filtration system is led into the collector of the compactor. An optical sensor starts a helix which transports the oil slime to a first press. There, the mass undergoes a 3:1 compression and a first amount of oil is recuperated. In addition to compacting the sludge, this first press also transports the dirt to a second cylinder. Another compression (7:1) takes place while the dirt is being led towards a third cylinder. Great force (1700 kg/cm) compacts the sludge a final time before removing it from the ma-chine. The recuperated oil is collected and pumped into the dirt tank of the filtration system.

3 consecutive presses compact the sludge and recuperate coolant