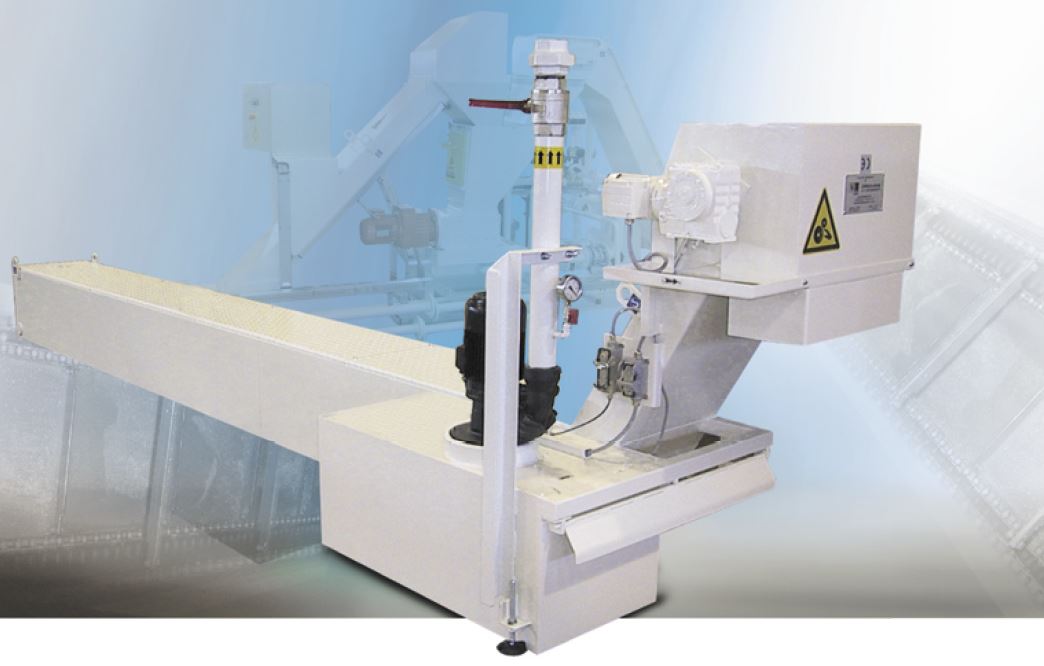

Scraper Conveyor

Our scraper conveyors are adapted for the transport of short broken chips. They can be used for chip removal from single machine tools or complete machine groups. Scraper conveyors can be combined with coolant tanks, pumps and suitable fi lter systems so as to form packages. They are available in 2 chain sizes: 38.1mm and 63 mm.

Scraper conveyor and link conveyor in one system

- Easy transport of all kinds of chips (even long chips or chip balls).

- No machine shut down during chip removal.

- Reliable and maintenance-free drive by worm-gear motor with automatic torque cut-out.

- Budget-priced designs due to the use of standard components.

- If combined with coolant supply and filter systems- exclusive solution to all your problems.

Mode of operation

The chips are transported by scraper strips which are drawn through the conveyor trough by steel-bushed roller chains mounted on both sides and guided in rails. Pushed by scraper strips, the chips slide over the steel plate bottom towards the outlet. In case of steep outlet slopes (over 45°) and chips are liable to adhesion, the conveyors are equipped with a wiping device at the outlet. The drive is by a worm-gear motor secured by an automatic torque cut-out system in case of conveyor blocking. As the geared motor is directly mounted on the drive shaft of the scraper conveyor, driving elements susceptible to wear such as roller chain, toothed gears, slipping clutch and such are eliminated.

Close-up