Paper Belt Filter

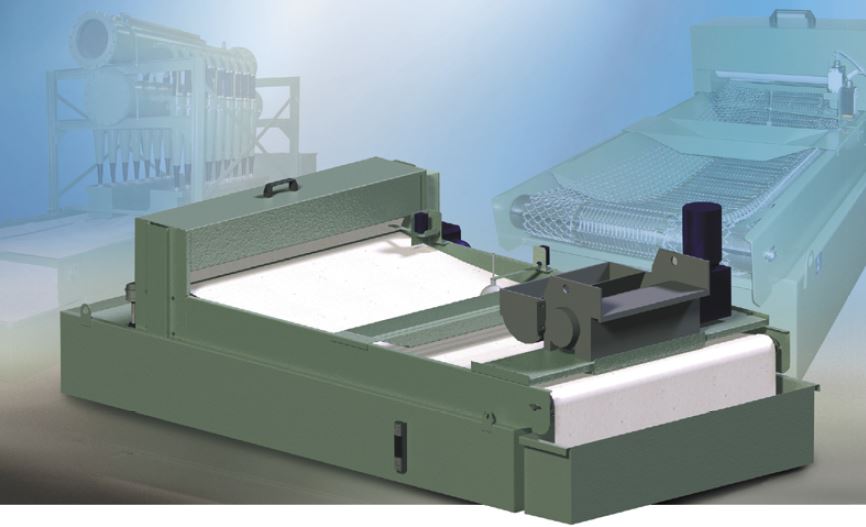

The paper belt filter is especially designed for cleaning cooling lubricant or other polluted liquids, used in the metal working industry. Depending on the dirty liquid, the filter can be equipped with a magnetic separator. A stainless steel version is also available.

Thanks to a reliable separation, even of specifically light and non-magnetic particles, a high degree of purification can be reached. This type of filter is extremely maintenance and user friendly.

Mode of operation

Design without magnetic separator

The strip-shaped filter paper supplied from a reel is supported and conveyed by a wire-mesh fabric with rollers. Through the appropriate moulding, fabric and paper form a filter bin in which the liquid to be cleaned flows through the filter paper into the clean coolant collecting tank, which is arranged under the filter bin.

Increasing pollution of the filter media will cause impermeability, resulting in an increased liquid level in the filter bin. Consequently, a float switch is actuated and the polluted filter paper will automatically be dragged out until the liquid level has fallen again and the switch-off point of the float switch has been reached. The filter paper with the pollutions is deposited in the bin and can be taken out and disposed without interrupting

the filtering process.

Design with magnetic separator

With this design, the liquid to be cleaned first flows under a constantly rotating magnetic roll during which process all magnetic foreign bodies are separated and, by means of an adjustable scraper, conveyed to the filter belt in the discharge area. The other filtering process is as described above. The magnetic preliminary separation results in a reduced dirt admission to the filter paper and thus in a reduced filter paper consumption.

Technical data

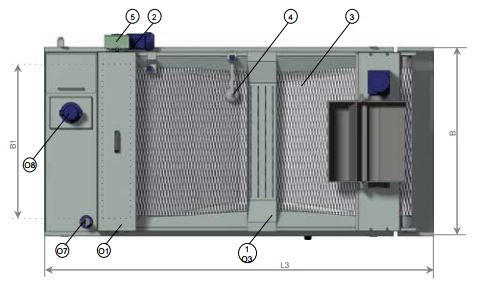

Standard

1. Inlet

2. Drive

3. Wire belt

4. Floater switch

5. Terminal box

6. Liquid tank

7. Swarf box

8. Filter fleece

Options

O1. Covering filter fleece

O2. Covering filter

O3. Inlet distributor

O4. Magnetic filter

O5. Fleece end switch

O6. Optical level

O7. Level switch

O8. Machine supply pump

O9. Electrical control cabinet

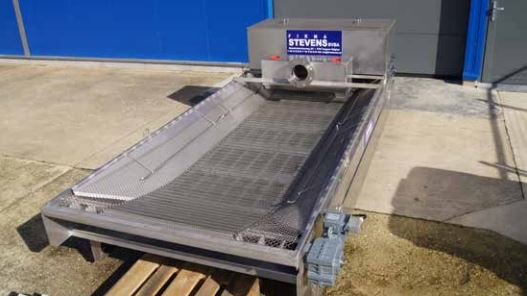

Examples