Hydro-vac Vacuum Filtration System

Worldwide service and engineered applications

Hydro-Vac is the “original” vacuum system for filtering metalworking liquids. More than 6,000 systems are installed worldwide. Firma Stevens-Hydrobelt stands behind every system with a worldwide sales and service network that solves problems and stocks spare parts and filter media. Application engineers and system designers use computer aided design techniques to tailor systems to end user needs. Our laboratories work with you to select the best system components and filter media to remove waste solids from fluids.

Increase tool life. Decrease Vacuum chamber liquid disposal costs.

Hydro-Vac vacuum filtration systems boost metalworking productivity. Tool life doubles, triples or more. Cooling and lubricating fluids can last indefinitely. Uptime climbs because of fewer tool changes and less machine maintenance. Chip disposal is simplified. Critical tolerances and surface finishes improve dramatically.

High reliability. Low cost operation.

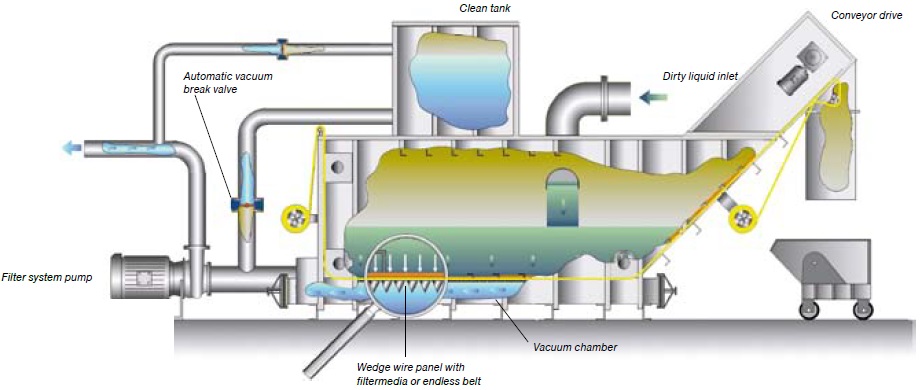

Hydro-Vac systems have only three moving parts: the filter/distribution pump, the flight conveyor and the vacuum break valve. This keeps maintenance low and system reliability high. Energy costs are low because the same pump generates filter vacuum and delivers pressurized liquid to production machines.

High-flow systems for plant wide filtration

Hydro-Vac systems filter mineral oils, soluble oils, semi-synthetic and other fluids at flow rates of up to 50,000 L/min. Self-contained centralized units can be installed above or below floor, or in mobile configurations to handle single machines, machine centers, departments or entire plants. Add optional, automatic chip processing and waste disposal for complete system efficiency.

Dual filtration for continuous operation.

Hydro-Vac systems use a unique dual technique to filter and recirculate process liquids. As dirty liquid enters the filter, floating debris and tramp oil is flushed to the discharge ramp and automatically skimmed of the surface by the filter conveyor flights. Simultaneously, liquid is drawn through the filter medium at the bottom of the dirty reservoir by a filter/distribution pump.

From the clean liquid vacuum chamber, the fluid is continuously pumped to the machines. Automatic operation is ensured by a preprogrammed filter cycle. Initiated automatically when a preselected vacuum is eliminated by backflow of clean liquid lifts the media to prevent migration during indexing. During the index cycle, clean liquid is drawn from a buffer tank to ensure a continuous supply to machines.

Hydro-Vac systems build up a concentrated solids cake which enhances filtration. The micro indexing feature permits retention of a concentrated solids cake on 90% of the filter area at all times. The filter’s ability to develop greater vacuum differential as the solids cake increases maintains uniform flow through the media.

Animation

Media options

Firma Stevens-Hydrobelt filter media are designed for specific applications ranging from rough machining to grinding, honing and polishing. Larger fines can be retained by permanent filter media such as stainless steel wedge wire and woven continuous belt media. Both are permanent-type media that can reduce operating costs. Particulates down to a 10 micron level are removed by low cost, disposable, non-woven media.

A permanent stainless steel wedge-wire bottom is built in as standard. This is done to let the filtered liquid pass and to support the media.

Disposable non-woven media. Filter finess from 200 to 10 microns.

Permanent synthetic endless belt up till 40 microns.

Examples