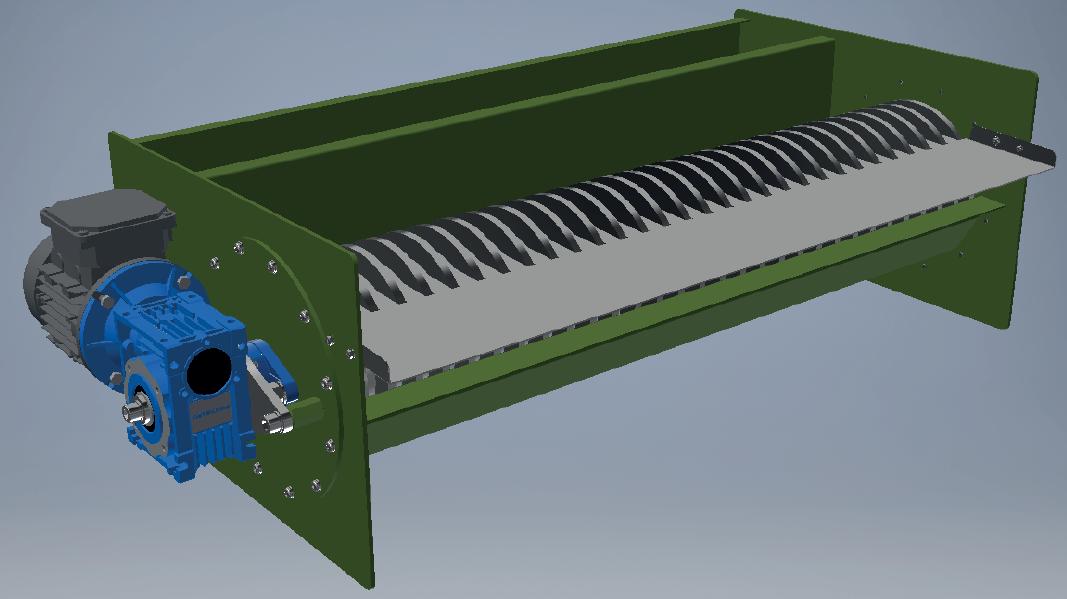

RMW filter - Magnetic Separator

The separators of this series have a magnetic rotating drum. The sludge is removed by a comb-like scraper.

The rotating drum, coming out of the machine tool, lets medium flow over the strongly magnetized steel discs. Thereby the ferritic impurities and most of the non-ferritic particles, such as grinding wheel-abrasion, are mechanically tightened. The sludge is transported and removed away by a comb-like scraper. A sloping plate is attached to it. Slipping of the sludge is fixed.

Technical specifications

The separators consist of:

- a strong frame made of welded sheet steel with bottom made of non-magnetic stainless steel and special protective coating.

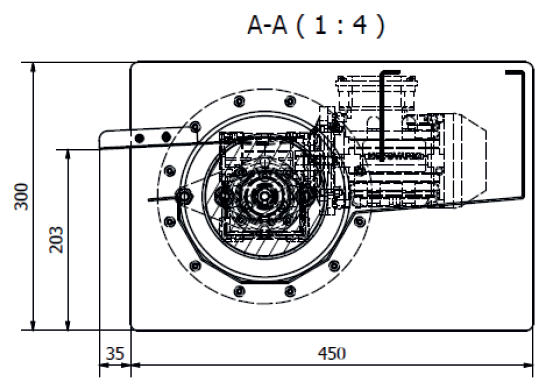

- a rotary drum made of sintered, annular permanent magnets arranged between steel discs.

These are mounted and fixed on a strong shaft, which is held by two flanges with largers. The very slow drum rotation is supported by a three-phase motor with 0.12 kW and reduction gear.

The main features of these filters are:

- extremely powerful permanent magnets, which expand the magnetic field through the steel discs.

- very low rotation speed of the drum.

- They are therefore suitable for the treatment of cooling media with smallest iron particles and the purification of pure cutting oils very effective.

- Virtually no maintenance costs are incurred.

Model

RMW - 60

RMW - 100

RMW - 160

RMW - 200

RMW - 300

RMW - 400

RMW - 500

RMW - 600

RMW - 700

RMW - 800

RMW - 900

RMW - 1000

Emulsion

60 L/min

100 L/min

160 L/min

200 L/min

300 L/min

400 L/min

500 L/min

600 L/min

700 L/min

800 L/min

900 L/min

1000 L/min

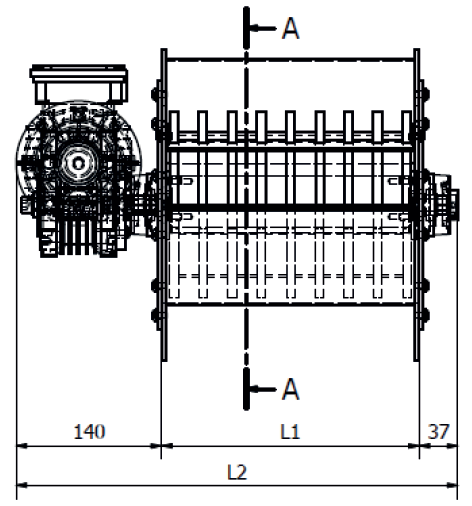

Dimensions L1

108

164

248

304

444

584

724

864

1004

1144

1284

1424

Dimensions L2

285

341

425

481

621

762

901

1041

1181

1321

1461

1601